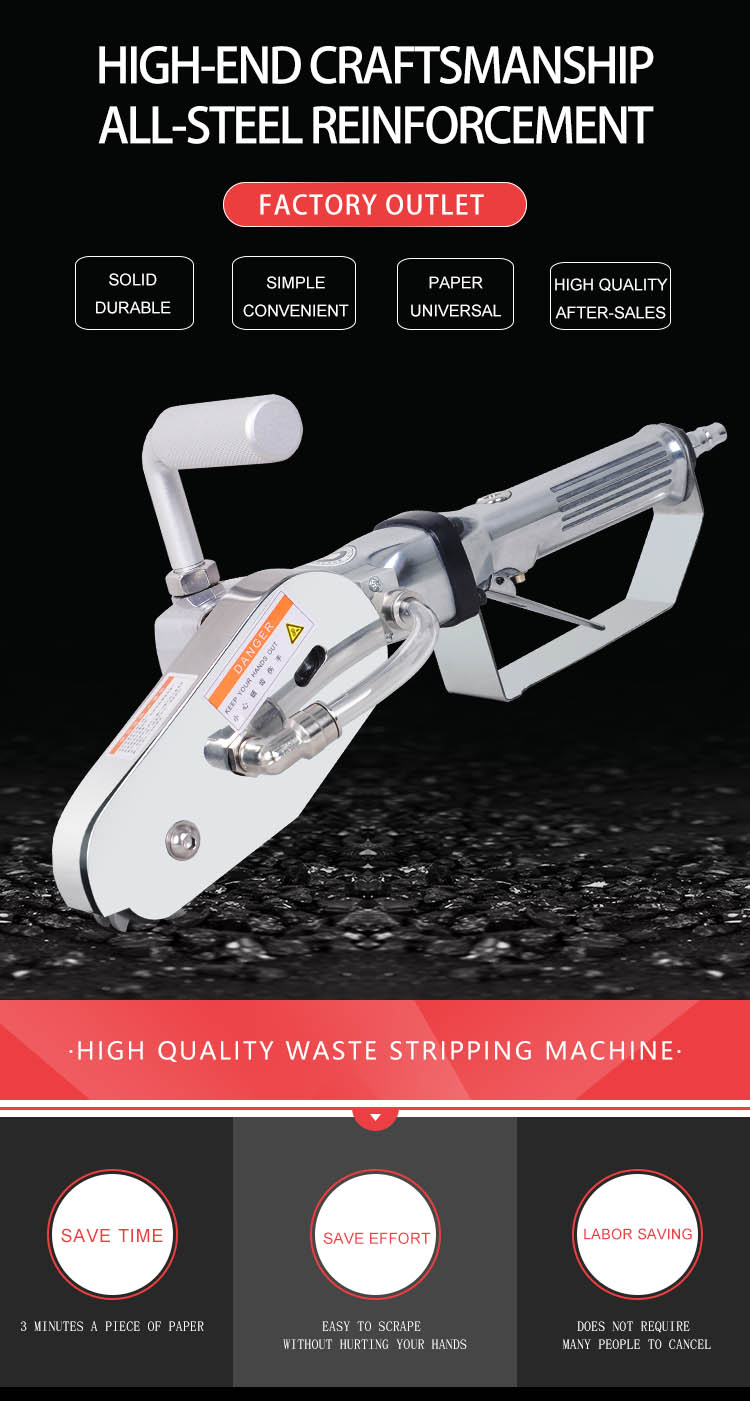

| Species: | pneumatic waste stripper | Model number: | HS-280 |

| Free speed: | 2500RPM | Inlet diameter: | 8*12mm |

| Air compressor: | ≥3.5kw |

Barometric requirement: |

0.6-0.8KPA |

| Net weight: | 3.5KG | Sprocket profile: | single row/middle teeth |

HUAXU carton waste stripper machine by ShenZhen HUAXU Machinery Co.,Ltd. R&D,production,sales,each product is to customer experience as the main guide to design. HUAXU die cutting pneumatic carton waste stripper machine chain with the latest rotating riveting technology,one-piece mechanical processing molding.

For order inquiries, please click:

The Role and Importance of Waste Stripper Machine in the Printing and Packaging Industry

In the fast-paced world of printing and packaging, efficiency and precision are key factors in ensuring high-quality output. One essential tool that plays a crucial role in streamlining the production process is the waste stripper machine. This innovative equipment, also known as a pneumatic carton stripper, is designed to remove waste material printed sheets, making it an indispensable asset in the printing and packaging industry.

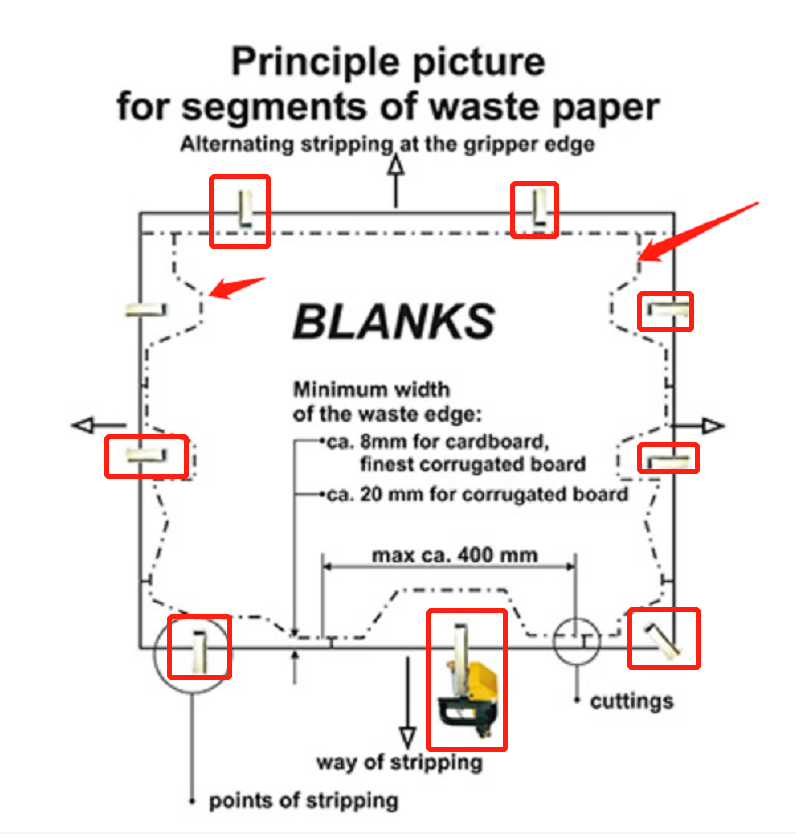

The waste stripper machine is a vital component in the post-printing process, particularly in the production of cartons, labels, and other packaging materials. Its primary function is to eliminate excess material, such as die-cutting scrap, the printed sheets, ensuring that the final product meets the required specifications and standards. This not only enhances the overall appearance of the packaging but also contributes to cost savings by minimizing material wastage.

One of the key features of the waste stripper machine is its pneumatic operation, which enables it to efficiently and accurately strip away waste material the printed sheets. The pneumatic system utilizes compressed air to power the machine, allowing for precise and consistent stripping of waste without causing damage to the printed material. This level of precision is essential in ensuring that the final product meets the exacting standards of the printing and packaging industry.

The waste stripper machine is equipped with advanced technology and automation capabilities, making it a highly efficient and reliable tool in the production process. Its automated functions enable seamless integration with the printing and packaging workflow, reducing manual intervention and increasing productivity. This not only saves time but also minimizes the risk of errors, resulting in a more streamlined and cost-effective production process.

In addition to its efficiency and precision, the waste stripper machine also plays a significant role in enhancing the overall safety of the production environment. By automating the waste removal process, it reduces the need for manual handling of sharp or potentially hazardous waste materials, thereby minimizing the risk of workplace injuries. This focus on safety aligns with industry standards and regulations, ensuring a secure and compliant working environment for production personnel.

Furthermore, the waste stripper machine contributes to environmental sustainability by minimizing material wastage and promoting resource efficiency. By effectively removing waste material from printed sheets, it reduces the amount of discarded material, leading to a more sustainable and eco-friendly production process. This aligns with the growing emphasis on sustainable practices within the printing and packaging industry, reflecting a commitment to reducing environmental impact.

The importance of the waste stripper machine in the printing and packaging industry cannot be overstated. Its role in streamlining the production process, enhancing quality, and promoting safety and sustainability makes it an indispensable asset for manufacturers and converters. By investing in advanced waste stripping technology, businesses can optimize their production capabilities, improve product quality, and achieve greater efficiency and cost-effectiveness.

In conclusion, the waste stripper machine, also known as a pneumatic carton stripper, is a critical component in the printing and packaging industry. Its ability to efficiently remove waste material printed sheets, coupled with its precision, automation, and safety features, makes it an essential tool for manufacturers and converters. As the industry continues to evolve, the waste stripper machine will remain a key factor in driving efficiency, quality, and sustainability in the production of packaging materials.

Shenzhen Huaxu Machinery Co., Ltd

Shenzhen Huaxu Machinery Co., Ltd