Parameters of Huaxu four-open inner hole waste stripper machine:

|

Machine Model: HS-650 |

Compressed air (bar): 6-8 |

|

Maximum waste cleaning format (mm): 720*500 (according to paper and material) |

Maximum stack height (mm): 70-100 |

|

Table height (mm): 800 |

Minimum clear inner hole position (mm): 3 |

|

Hole clearing speed (times/min): 15-20 |

Maximum pressure (T): 1.5 |

|

Dimension(mm):850*660*1600 |

Machine net weight (kg): 175 |

|

Supply voltage (V): 220 |

Frequency (Hz): 50/60 |

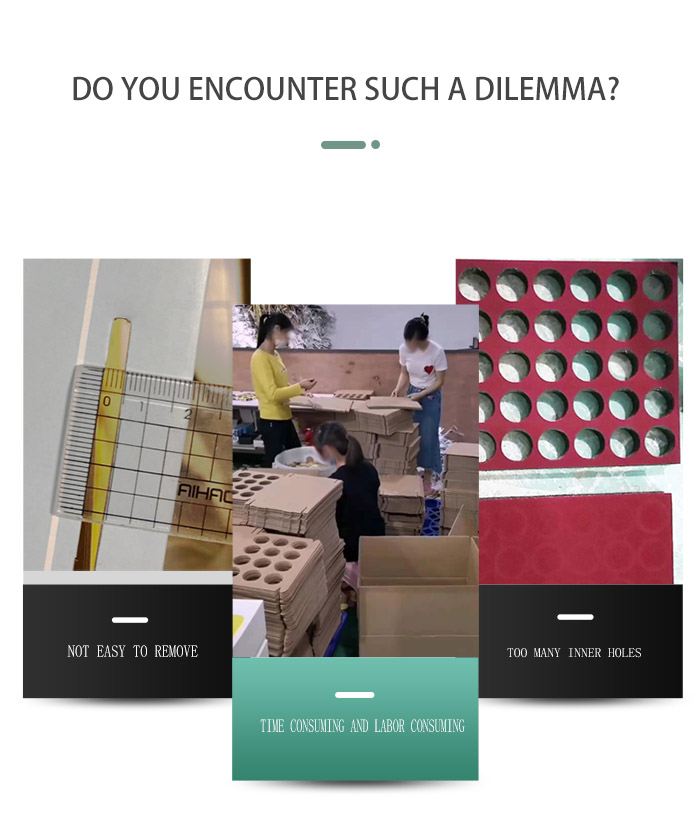

The HS-650 inner hole waste stripper is a cutting-edge machine designed to efficiently remove carton waste the inner holes of carton packaging. This innovative equipment is equipped with advanced features that make it a valuable asset for businesses in the packaging industry.

One of the key features of the HS-650 inner hole waste stripper is its precision and accuracy in removing waste the inner holes of cartons. The machine is designed to handle various sizes and shapes of inner holes, making it versatile and adaptable to different packaging requirements. This ensures that the waste-stripping process is thorough and consistent, resulting in high-quality finished products.

Another notable feature of the HS-650 inner hole waste stripper is its efficiency and speed. The machine is capable of handling a high volume of cartons, making it ideal for large-scale production operations. Its automated processes and quick setup contribute to increased productivity and reduced downtime, ultimately leading to cost savings for businesses.

Furthermore, the HS-650 inner hole waste stripper is designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and controls allow operators to set up and adjust the machine with ease, minimizing the need for extensive training and technical expertise. Additionally, the machine is built with durable components, ensuring long-term reliability and minimal maintenance requirements.

In conclusion, the HS-650 inner hole waste stripper is a state-of-the-art machine that offers a range of features to enhance the waste-stripping process for carton packaging. Its precision, efficiency, and user-friendly design make it a valuable investment for businesses looking to streamline their production processes and improve the quality of their finished products. With its advanced capabilities, the HS-650 inner hole waste stripper sets a new standard for waste-stripping machines in the packaging industry.

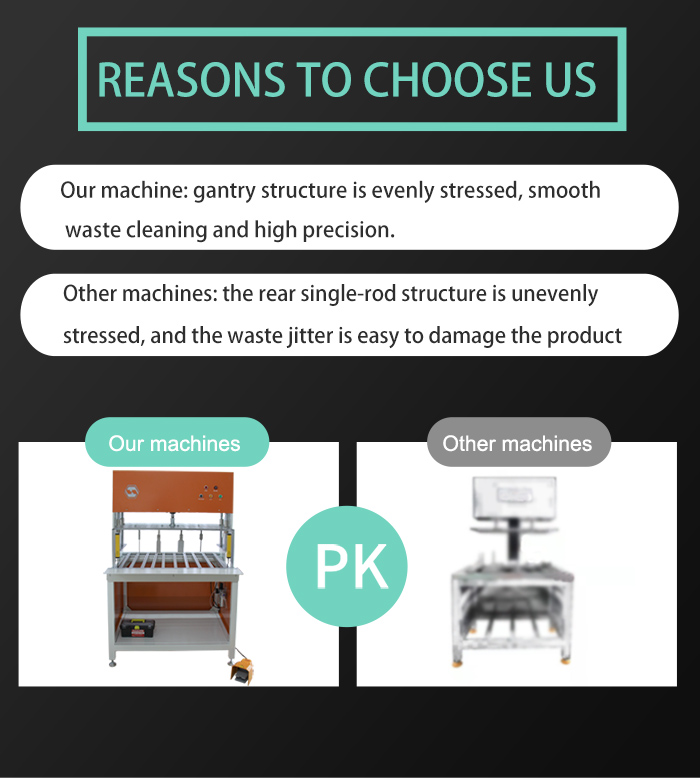

Advantages:

1. Offers high precision and user-friendly operation.

2. Customizable mold with adjustable punching die, allowing for the installation of multiple molds to clean numerous waste holes simultaneously.

3. Simultaneous clearance of multiple holes enhances work efficiency.

4. Applies pressure to the product without compromising its integrity.

5. Equipped with an integrated paper confetti collection bin.

How to do it:

1. This equipment adopts single-phase 220V power supply and uses compressed air as the power source. Stable air pressure 6-8kg.

2. Turn on the power switch, put the product on the working platform, use the paper positioning plate to set the product in position, the switch is marked with "manual", and the ejector pin is installed in the vacant position.

3. After the ejector pin is installed, jog the upper and lower switches to check whether the ejector pin is aligned with the hole position, and after alignment, set the switch as "automatic".

4. Enter the working state, each time the paper is not higher than the paper baffle, and the product is placed neatly, step on the foot switch.

Shenzhen Huaxu Machinery Co., Ltd

Shenzhen Huaxu Machinery Co., Ltd